Test Device Evaluation

Test Device

We can fabricate test devices such as OLEDs and organic or perovskite solar cells.

Our standard test device sizes are 30 x 30 mm2 substrate and 2 x 2 mm2 active area. The size can be changed upon request.

-

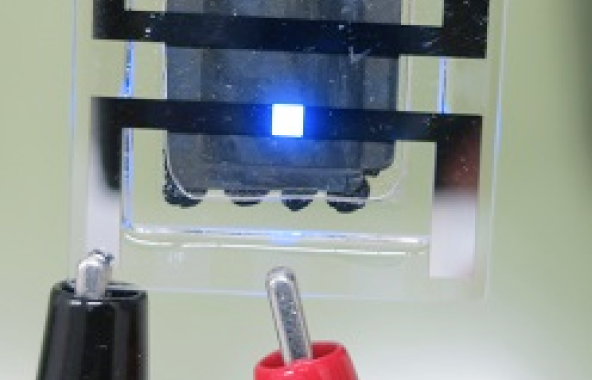

OLED

We can fabricate and evaluate OLED devices in our company. The photo on the right shows an example of a blue OLED device fabricated by our company.

-

Vacuum Evaporation Equipment

Our vacuum evaporation equipment achieves a vacuum of 4x10-4Pa. In addition to organic materials, we can also perform vapor deposition of aluminum, silver, molybdenum oxide, and other materials. In addition to vacuum evaporation, films can also be formed by spin coating in a glove box. For the stable evaluation of the fabricated devices in air, thet can be encapsulated in a glove box using a sealing cap with a desiccant material.

-

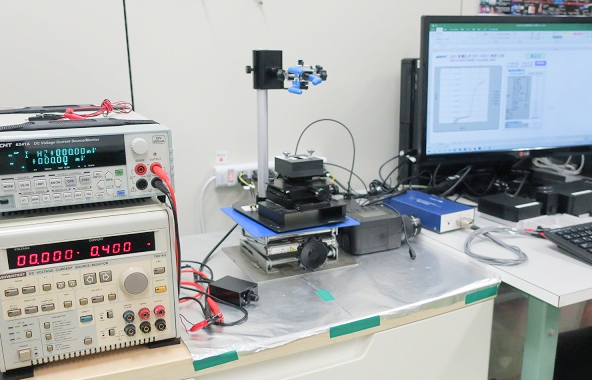

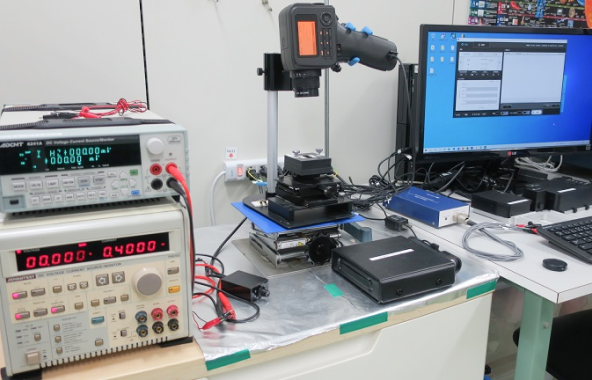

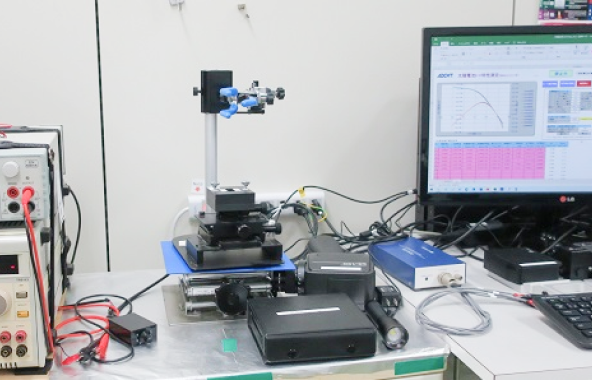

Automatic I-V Measurement System

The fabricated devices can be evaluated for voltage-luminance-emission characteristics, luminescence chromaticity, and luminescence spectrum using our equipment.

-

Luminance and lifetime measurement system

Luminance and driving voltage change with operation time can be evaluated, which are important parameters for device lifetime.

-

Organic solar cell

We can fabricate and evaluate organic solar cells in-house. The photo on the right shows an example of an organic solar cell using P3HT+PCBM fabricated at our company.

-

Process in glove box

In a nitrogen filled glovebox, thin layers of materials can be formed by the spin-coating method and baked on a hot plate. We can also encapsulate the films in a glove box using a sealing cap with desiccant, whic make it possible to evaluate the films stably in air .

-

Automatic voltage-current evaluation system

Using the solar simulator as a light source, the voltage-current characteristic can be automatically evaluated and the important factors such as energy conversion efficiency can be calculated.

Contact us

Contact us for R & D and

property testing