Sublimation purification

Sublimation purification

Train sublimation is a method of purifying raw materials by the differences in the sublimation and deposition temperatures from inpurities. It is an important purification method for organic semiconductors and is widely applied to low-molecular-weight OLED materials. We use our own patented sublimation purification method to achieve both of hign purity and high yield.

Patent No; JP6432874 and JP6700515.

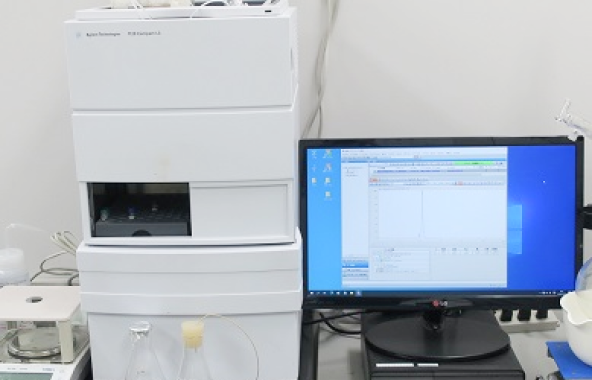

We can also evaluate the purity of purified and unpurified materials by liquid chromatography.

-

Inner tube Connection

Our inner tube connection method is original and patented which uses metal screws to connect the inner tubes with each other. This method minimizes the gap between the inner tube connections and reduces the loss of material leaking from the gap, resulting in a high material yield.

-

Specification of the equipment

Our sublimation equipment is capable of vacuum in the 10-3 Pa range and temperatures from 100 to 500°C. By changing the size of the sublimation tube, it is possible to process 0.1 g to 5 g per refining. It can perform the purification with minimized material loss. We can also process dozens of grams by performing multiple runs.

-

Purity evaluation

The purity improvement can be evaluated by liquid chromatography.

Quantitative evaluation is achieved by the method.

Contact us

Contact us for R & D and

property testing